Reverse polarity in welding refers to the electrode being connected to the positive terminal of the power source. This configuration is commonly used in certain welding processes for specific applications. It plays a crucial role in determining the welding characteristics, such as penetration and heat input. Understanding the concept of reverse polarity is essential for welders to achieve desired results and ensure the quality of the weld joint. Let’s delve deeper into the significance and practical implications of reverse polarity in welding.

What is Reverse Polarity in Welding

Welcome to our guide on reverse polarity in welding! If you’ve ever been curious about how welding works or if you’re considering a career in welding, understanding reverse polarity is a fundamental concept to grasp. In this article, we’ll delve into the world of welding and uncover the mystery behind reverse polarity.

Introduction to Welding

Before we explore reverse polarity, let’s first understand what welding is all about. Welding is a process that is used to join two or more pieces of metal together by melting them. This process is crucial in various industries, from construction to automotive manufacturing.

Basics of Electrical Polarity

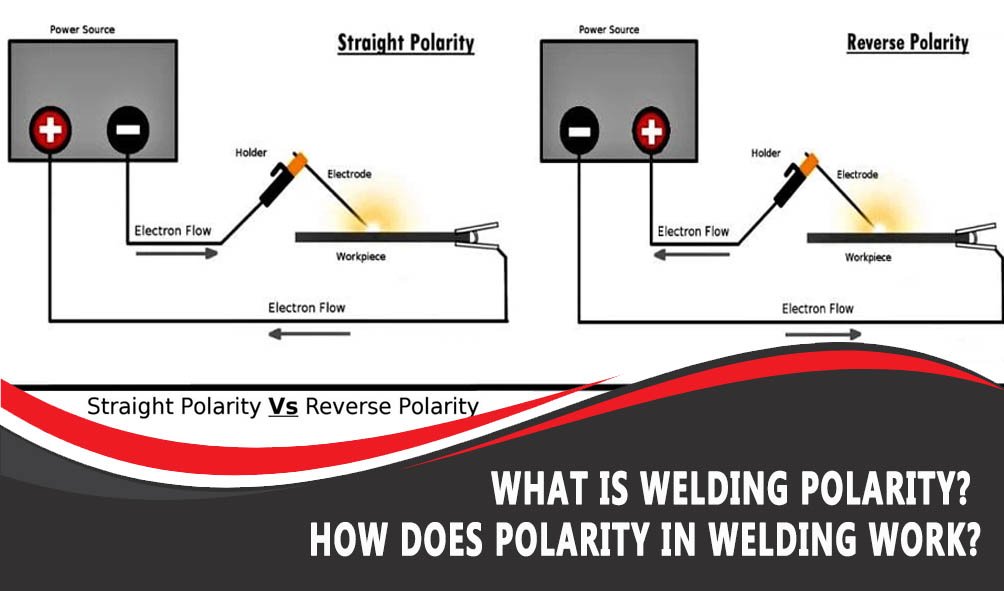

Electrical polarity refers to the flow of electric current in a circuit. In welding, polarity plays a significant role in determining the quality of the weld and the overall welding process. There are two types of polarity used in welding: direct current (DC) and alternating current (AC).

Direct Current (DC)

DC welding involves the flow of electric current in one direction, either from the electrode to the workpiece (electrode positive) or from the workpiece to the electrode (electrode negative). The choice of polarity depends on the welding process and the type of metal being welded.

Alternating Current (AC)

AC welding involves the reversal of electric current direction at regular intervals. While AC welding is versatile, DC welding is more commonly used due to its stability and better control over the welding process.

Understanding Reverse Polarity

Now, let’s delve into reverse polarity, a term you may have heard in welding discussions. Reverse polarity refers to the setting where the electrode is connected to the positive terminal and the workpiece to the negative terminal in a DC welding circuit.

When using reverse polarity, the electrode becomes the anode (positively charged) and the workpiece becomes the cathode (negatively charged). This setup has specific advantages and is often used in certain welding applications.

Advantages of Reverse Polarity

One of the primary advantages of using reverse polarity in welding is improved penetration. The heat generated by the positively charged electrode concentrates at the point of contact, resulting in deeper penetration into the workpiece.

Additionally, reverse polarity helps to reduce spatter during welding, leading to cleaner and neater welds. The control over the welding process is enhanced, allowing for precise and efficient welding operations.

Applications of Reverse Polarity

Reverse polarity is commonly used in welding thick metals, such as stainless steel and aluminum. The increased penetration provided by reverse polarity is beneficial when working with thicker materials that require a strong, durable weld.

Furthermore, reverse polarity is preferred in overhead welding positions where gravity can affect the molten metal flow. The enhanced control and reduced spatter make reverse polarity ideal for challenging welding scenarios.

In conclusion, reverse polarity in welding is a valuable technique that offers improved penetration, reduced spatter, and enhanced control over the welding process. Understanding the role of polarity in welding is essential for achieving high-quality and durable welds across various applications.

We hope this guide has shed light on the concept of reverse polarity in welding and its significance in the welding industry. Whether you’re a welding enthusiast or a beginner in the field, mastering the basics of polarity will set you on the path to becoming a skilled welder.

Stick Welding Polarity Explained: AC vs DCEP vs DCEN

Frequently Asked Questions

What causes reverse polarity in welding?

Reverse polarity in welding occurs when the electrode or the workpiece is connected to the positive terminal of the power source, causing the electrode to act as the anode. This setup can result from incorrect cable connections or improper electrode selection.

How does reverse polarity affect the welding process?

Reverse polarity can lead to insufficient penetration, weaker welds, increased spatter, and poor bead appearance. It can also cause unstable arc characteristics and impact the overall quality and strength of the weld joint.

What are the dangers of using reverse polarity in welding?

Using reverse polarity in welding can pose safety risks such as electric shock, overheating of equipment, and potential damage to the welding machine. Incorrect polarity settings can also increase the likelihood of defects and weld failures.

How can welders detect and correct reverse polarity issues?

To detect reverse polarity, welders can perform a simple test using a magnetic compass to determine the direction of the magnetic field around the electrode. Correcting reverse polarity involves switching the cable connections to ensure the workpiece is connected to the positive terminal and the electrode to the negative terminal.

What are the advantages of using the correct polarity in welding?

Using the correct polarity in welding ensures proper heat distribution, weld penetration, and bead appearance. It can improve overall weld quality, efficiency, and the integrity of the welded joint, leading to stronger and more reliable welds.

Final Thoughts

Reverse polarity in welding refers to the electrode being connected to the positive terminal. This configuration allows for deeper penetration and faster welding speeds. It is commonly used for welding thicker materials and in applications requiring higher heat input. Understanding what reverse polarity in welding is can help welders achieve better control and efficiency in their welding process.